Production line logistics

Customers benefit from this service on a daily basis

Production line logistics

Production line logistics represent the full scope of logistical activities carried out within the production lines, up to the manufacturing process itself. This process includes strategic point planning of required materials for the production stations, timing of maneuvering the material from the rear warehouse, preparing the material for production (unpacking, etc.), dispensing the required material to production lines, disposing of packaging and excess materials derived from the production lines, handling RMA & RJ within the production lines back to the rear warehouse, handling FG (Finished Goods) packaging, etc. Our goal is to enable the personnel working in the production lines to focus solely on manufacturing operations, while we provide the entire envelope of material flow, in and out of the production lines.

Storage and Inventory Management Services

Fritz operates four logistics centers measured at 40,000 square meters, located in Caesarea and Kiryat Gat, adjacent to main traffic routes. The storage capabilities and advanced services operate in a variety of models, and are adapted to meet a wide array of storage and management standards.

Value Added Services

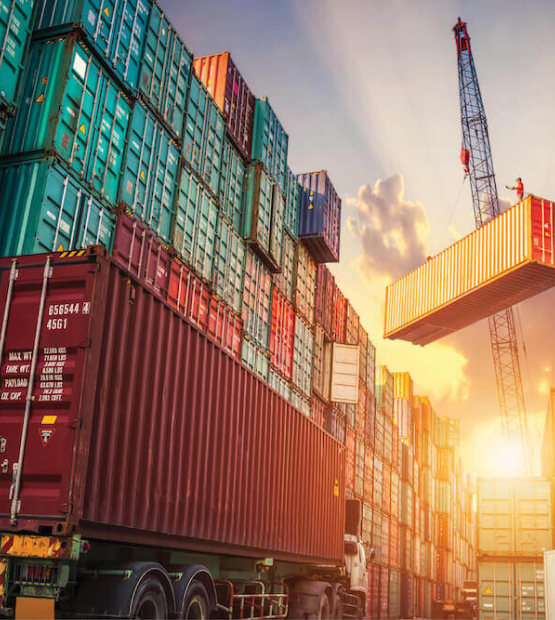

As part of the envelope of services provided to our customers at Fritz, we also offer value-added services, designed to assist our customer with additional needs, such as: emptying of containers, control and reception of goods, picking and dispatching for on-demand shipments, production of custom packaging, kit assembly according to customer specifications, item conversion, tagging/welding, sticker attachment, handling returns, disposal, inventory replenishment, stock counting and more.

VMI Services

Our Vendor Managed Inventory (VMI) services at Fritz enable companies and suppliers to better organize, streamline, and optimize their manufacturing, distribution, and supply chain. Our logistics centers can serve as a forwarding warehouse for you, based on your inventory forecasts. VMI services provide you with a comprehensive logistics solution that combines maximum inventory availability and Just-In-Time (JIT) delivery, without logistical compromises or material shortages. As a result, significant savings can be achieved in floor space, inventory costs, cash flow, and production continuity. From the supplier’s perspective, this solution allows for longer production runs, optimization of the transportation system, and offers greater certainty. Our logistics information systems are designed to handle the VMI item population that is not recorded in your books, enabling quick and easy integration of items into inventory, virtually and without physically maneuvering the items. This service leverages our logistics strength and expertise to provide a reliable and profitable solution for both parties.

WeLog Services

WeLog services are collaborative logistics services allowing customers in need of personally tailored services, designed to match their ever-changing business needs, to benefit from logistics services based on operational volume (square meters and reduced inventory quantities) without fixed expenses, but rather using a payment on demand model. With this, you can benefit from our logistics services, using the advanced technology that enables you and your company to easily track your shipments from anywhere, by means of any digital device.

Servitz: Revolutionizing Service

In the fast-paced world of business, staying ahead of the competition requires innovative solutions and cutting-edge technologies. Fritz, a forward-thinking company, has recognized this need and established a dedicated digital department to drive innovation and digital development. One of their remarkable achievements is the development of Servitz, an app that has transformed the company’s service, logistics, operations, and business intelligence.